I have some news. The minimum viable van is no longer viable.

We’re in Wellington and we’re heading south towards the mountains, snow and glaciers next week. We need a stable, spacious campervan bed that will keep us warm during a New Zealand south island Winter. Oh, and an indoor van-desk since we’re working remotely on the road. Occasionally.

We’ve made a great start this week, so I thought I’d share a few snaps and notes on our progress.

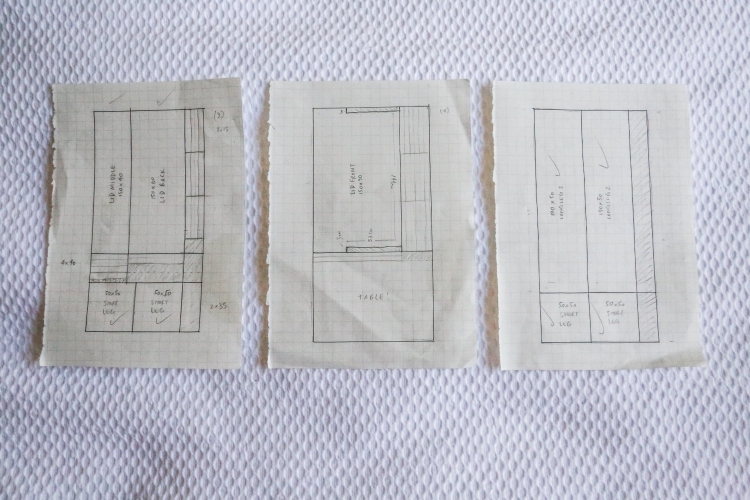

1. We sketched and re-sketched our design on paper and in 3D software

We wanted to build a temporary bed, figuring this would be a selling point for our van’s future owner. That lucky person will be able to use the van for recreation AND for transporting all their big things. Yay!

So we sketched out manageable components that can be slotted together and removed again without any screws on paper. Then we used Sketchup to bring our design to life in 3D.

Our confidence in the sturdiness of the aluminium modular system I wrote about previously had waned, so we opted for plywood in the end. We had also initially wanted to convert the bed to a desk to work from during the day. We soon realised we could make a seat from the end of the bed, and add a removable table behind the passenger seats to avoid the fold-up/fold-down daily dramas.

2. We built a balsa wood model

These balsa sticks are light and easy to cut with a craft knife. We picked them up on a recent trip to Australia and a large packet cost about $16 AUD. It’s a cheap way to prototype your a design and hone it as you go. It’s made at a 1:10 scale.

3. We shopped around for some plywood and made a to-scale template from graph paper

These templates helped us work out the best way to cut our components from the plywood. They came in sheets of 1.2 metres x 2.4 metres, 18mm thick. We toyed with the idea of a 22mm thick sheet, but they didn’t have any available on the day. Gah, I hope that’s going to be strong enough.

4. We paid a guy with a big machiney thingy to make accurate cuts in our plywood

And now we’re up to date, with (hopefully) all the pieces we need.

I’ve written before about making things cheap to test and change, plus the benefits of a minimum viable campervan. Whack some camp beds in the back of a regular van and bam! You have a home on wheels.

While camp gear can get you in a new van-home and on the road in less than 24 hours in Summer, when the weather turns, one needs to venture into something a little more… well, warm.

Custom-built campervan furniture is a lot more expensive and labour-intensive to test and change. The buy-a-bunch-of-timber-and-see-how-it-goes approach might work for those with tools and experience, but we had neither.

When you’re working with physical materials, an up-front design phase can help you save money and waste. Save the trees! If you’re building software or delivering organisational change projects however, an up-front design phase is not so necessary and usually not so expensive to change. So long as you start small (see Agile rant below).

If you’re doing what we’re doing, you probably don’t need to sketch your design in 2D, 3D AND make a balsa wood model. Our nerves clearly got the better of us and we erred on the side of planning.

We’ll soon find out whether our fairly detailed planning decision *actually* saves any trees. Because that’s the issue with detailed up-front planning right there: it’s all theory. Or paper. Or 3D models. You just don’t know if it’ll work until you start building it.

Will it be stable and warm? Who knows!

Whacking the bits together starts now. I’ll breathe again when I see all the pieces fit.

<agile rant>

Notes on the featured image: I spotted this billboard on the road between Wellington and Lower Hutt this week. I’ll probably get a lot of use out of this pic for future conference talks or Agile training materials. Being Agile or Lean however, doesn’t mean zero planning -this is one of the most common misnomers I come across in my work. Agile teams typically plan their work on demand or in 1-2 week routines. They avoid your standard long-term gantt chart style planning, and avoid planning any detailed activities that are way way way in the future. Planning is still a thing, but happens far more frequently. And this is because Agile teams know long term planning is flawed. They know they need to build the thing to see if they’ve fixed the need or the problem or the bed-desk. I think I’ll go have a beer.

</agile rant>

Good rant. You hit the important point right on the head. A bit of advanced thinking is needed but you don’t want to have 6 months of planning for the trip you are starting in 3 months.

Good luck on the van upgrade.

LikeLike

Cheers John. Analysis paralysis comes to mind… We simply don’t have the time for that! 🙂

LikeLike